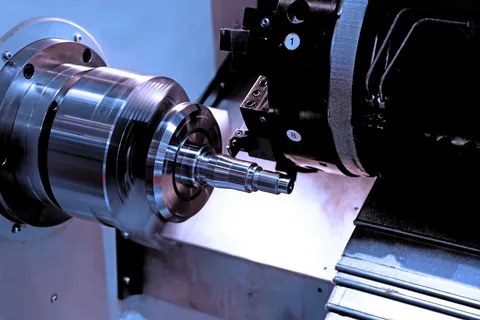

Lathe machines are essential tools in the world of manufacturing. They help shape materials like metal, wood, and plastic by rotating the material against a cutting tool. In simple terms, a lathe machine holds and spins a material, allowing a cutting tool to remove excess material and shape it into the desired form. This process is known as “turning.” There are different types of lathe machines, each designed for specific tasks. In this blog, we’ll take a closer look at the various types of lathe machines, their uses, and how they contribute to modern manufacturing.

What is a Lathe Machine?

A lathe machine is a versatile tool used in machining, primarily for shaping, cutting, drilling, or sanding materials. The machine works by holding the material in place while it is rotated at high speeds. The rotating material is then shaped by a cutting tool, which can move along different axes to achieve the desired shape. Lathe machines are used in a wide range of industries, including automotive, aerospace, medical device manufacturing, and woodworking.

Note – If you’re looking for high-quality lathe machining in Dubai, look no further than Raysun Techno Industries LLC. With a team of skilled professionals and state-of-the-art equipment, they provide precise and efficient lathe machining services tailored to meet your specific needs. Whether you’re in the automotive, aerospace, or industrial sector, Raysun Techno Industries LLC ensures your projects are completed with the highest standards of accuracy and craftsmanship. Reach out today to discuss your requirements and get a personalized quote for your next lathe machining project in Dubai.

The Different Types of Lathe Machines

Lathe machines come in many different forms, each designed for specific applications. Let’s explore the most common types of lathe machines and their uses.

1. Engine Lathe Machine

The engine lathe is the most widely used type of lathe machine. It is known for its versatility and can perform a variety of tasks like turning, drilling, and facing. Engine lathes are typically used for small to medium-sized workpieces, such as shafts, rods, and small parts. These machines are capable of producing high-precision parts, making them a go-to choice for industries like automotive and tool manufacturing.

Key Uses:

- Shaping cylindrical parts like rods and shafts

- Drilling holes in parts

- Performing threading operations

- Turning and facing operations

Why Choose an Engine Lathe?

- Versatility: It can handle various operations with minimal adjustments.

- Precision: Ideal for producing parts with high precision and tight tolerances.

- Cost-effective: Commonly available and affordable for small-scale production.

2. CNC Lathe Machine

CNC (Computer Numerical Control) lathes are a modern version of traditional lathe machines. These machines are automated and operated through a computer program, making them extremely precise and efficient. CNC lathes are used for mass production of parts where high precision and repeatability are required. They are commonly found in industries like aerospace, automotive, and medical device manufacturing.

Key Uses:

- Producing complex shapes with high accuracy

- Mass production of parts like gears, pulleys, and valve bodies

- Automated operations for consistent results

Why Choose a CNC Lathe?

- High precision: CNC lathes can achieve incredible accuracy and repeatability.

- Automation: They reduce human error and can operate for long hours with minimal supervision.

- Versatility: Capable of producing a wide range of complex shapes and sizes.

3. Turret Lathe Machine

A turret lathe machine is designed for repetitive production runs. It features a rotating turret that holds multiple tools, allowing the operator to switch between tools quickly without stopping the machine. This makes turret lathes ideal for mass production of small to medium-sized parts, like screws, bolts, and nuts.

Key Uses:

- High-volume production of simple parts

- Operations like drilling, boring, and facing

- Producing parts that require multiple operations in one setup

Why Choose a Turret Lathe?

- Speed: The ability to quickly change tools increases production efficiency.

- Consistency: It delivers consistent results over long production runs.

- Cost-effective: Ideal for high-volume, low-cost parts.

4. Slant Bed CNC Lathe Machine

Slant bed CNC lathes are similar to traditional CNC lathes, but they feature a slanted bed. This design provides better chip removal, which is important when machining metals like aluminum and steel. The slant bed also allows for better rigidity and higher cutting speeds, making it suitable for more demanding operations.

Key Uses:

- High-precision machining of metals

- Heavy-duty cutting tasks like drilling and threading

- Operations where quick chip removal is necessary

Why Choose a Slant Bed CNC Lathe?

- Faster chip removal: The slanted bed helps in quick and efficient chip removal.

- Higher rigidity: Provides better stability during heavy-duty cutting tasks.

- Better performance: Ideal for more complex operations that require higher cutting speeds.

5. Bench Lathe Machine

A bench lathe is a small, compact machine that sits on a workbench. It is typically used for lighter tasks and smaller workpieces. Despite its small size, a bench lathe can perform basic lathe operations like turning, sanding, and drilling. This type of lathe is perfect for hobbyists, small workshops, and educational purposes.

Key Uses:

- Small-scale turning and shaping tasks

- Working on smaller parts like jewelry or model components

- Basic operations in home workshops or educational settings

Why Choose a Bench Lathe?

- Compact design: Takes up less space, making it suitable for small workshops.

- Easy to use: Perfect for beginners and hobbyists.

- Affordable: Less expensive than larger lathe machines.

6. Automatic Lathe Machine

An automatic lathe machine is designed for high-volume production. These machines can perform multiple operations automatically without much human intervention. Automatic lathes are equipped with automatic tool changers and material feeders, making them ideal for producing large quantities of parts with minimal downtime.

Key Uses:

- High-speed production of parts like screws, bolts, and fasteners

- Manufacturing small parts in large quantities

- Jobs that require automatic material handling

Why Choose an Automatic Lathe?

- High production rate: Great for producing large volumes of identical parts.

- Reduced human intervention: Automatic features reduce the need for manual labor.

- Consistency: Provides consistent results with minimal error.

7. Collet Lathe Machine

A collet lathe uses a collet to hold the material being worked on. Collets are specialized fixtures that grip the material securely, allowing for highly precise turning operations. Collet lathes are commonly used for small parts that require tight tolerances and are often used in industries like electronics, jewelry, and medical device manufacturing.

Key Uses:

- Precision turning of small parts

- Working on parts that require high accuracy

- Manufacturing delicate components like electronics or jewelry

Why Choose a Collet Lathe?

- High precision: Collets provide a secure hold for highly accurate machining.

- Ideal for small parts: Perfect for tiny components that require fine details.

- Reliable: Offers high stability during the machining process.

Choosing the Right Lathe Machine for Your Needs

Selecting the right lathe machine for your manufacturing needs depends on several factors, such as the type of material you’re working with, the size of the parts, the precision required, and the production volume. Here are some key points to consider when choosing a lathe machine:

- Production Volume: For large production runs, automatic lathes or turret lathes may be the best choice. For smaller batches or custom jobs, an engine lathe or CNC lathe might be more appropriate.

- Material Type: Different lathe machines work better with different materials. For example, slant bed CNC lathes are ideal for metals, while bench lathes are better for softer materials like wood or plastic.

- Precision Needs: If you require very high precision, CNC lathes or collet lathes are great options. They are ideal for parts that need tight tolerances.

- Budget: CNC lathes and automatic lathes are typically more expensive, while bench lathes are more affordable but limited in capabilities.

Conclusion

Lathe machines are indispensable tools in modern manufacturing, offering a wide range of capabilities to suit different production needs. Whether you need to produce small parts with high precision or high-volume components quickly, there’s a lathe machine for the job. Understanding the different types of lathe machines and their uses is essential for selecting the right one for your specific needs. By carefully considering factors like production volume, material type, and precision requirements, you can make an informed decision and enhance your manufacturing process.

For more insightful articles related to this topic, feel free to visit blogsact.com