When it comes to labeling electrical panels, safety and clarity aren’t optional. A high-quality label provides more than information—it helps prevent accidents, ensure compliance, and keep operations running smoothly. That’s why phenolic labels for electrical applications have become the industry standard.

Made from durable, heat-resistant material, phenolic labels withstand extreme conditions. They won’t fade, crack, or peel like stickers or painted markings. Whether labeling circuit breakers, control panels, or high-voltage equipment, these engraved labels provide a permanent solution for electrical identification.

Why Phenolic Labels Are Essential for Electrical Applications

The wrong label can lead to costly mistakes or safety hazards in an industry where precision matters. Phenolic labels solve that problem by offering:

✔ High Visibility – Laser-engraved text ensures crisp, legible markings.

✔ Long-Lasting Durability – Resistant to heat, moisture, and chemicals.

✔ Non-Conductive Material – Ideal for high-voltage environments.

✔ Custom Engraving Options – Allows specific labeling needs like serial numbers, panel

IDs, and warning signs.

✔ OSHA and NEC Compliance – Helps meet electrical safety regulations with clear identification.

In environments where electrical hazards are a concern, labels must remain intact for years. A faded or missing label can result in costly repairs, equipment damage, or even injury. Many electricians, contractors, and facility managers choose engraved phenolic labels over alternatives.

Where Phenolic Labels Are Used

Professionals across electrical, industrial, and commercial fields rely on phenolic labels for various critical applications.

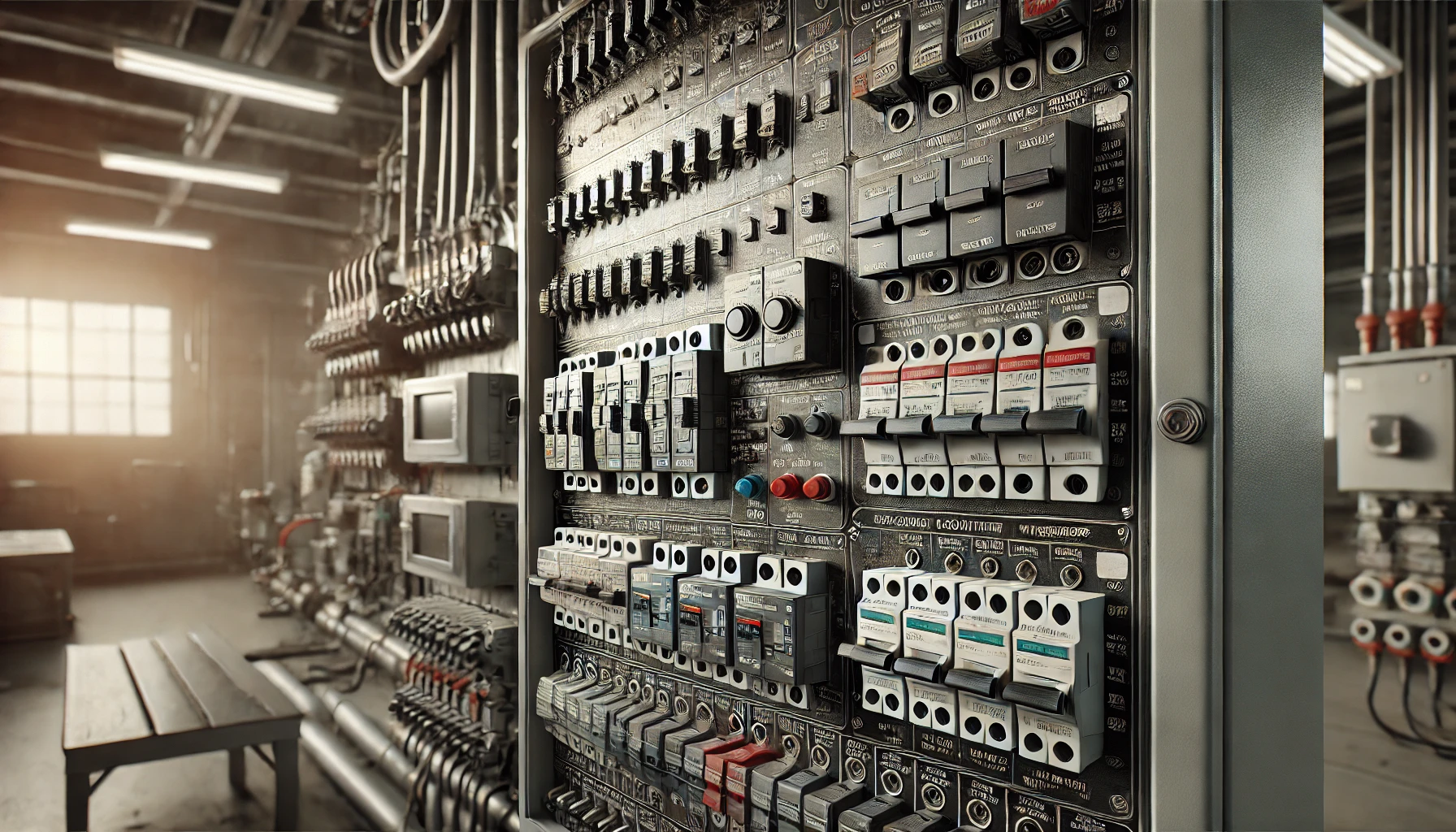

1. Electrical Panels and Breaker Boxes

Every switch, breaker, and connection needs to be clearly labeled. Misidentifying circuits can lead to power failures or safety risks in a high-stakes environment. Engraved phenolic labels ensure every breaker and control panel is marked correctly, reducing confusion for electricians and maintenance teams.

These labels also help with troubleshooting and repairs. If a circuit trips or a breaker needs to be shut off, having easy-to-read, permanent identification saves time and prevents errors.

2. High-Voltage Equipment

Visibility is everything when dealing with dangerous electrical currents. A faded label or a missing warning sign could result in serious accidents. Phenolic labels stay intact even in high-heat, high-voltage environments, making them ideal for transformer stations, power grids, and industrial machinery.

High-voltage labels often include safety warnings, voltage ratings, and lockout/tagout (LOTO) instructions. Custom engraving ensures that every label meets industry requirements while remaining legible over time.

3. Control Panels and Switchgear

Complex electrical systems in manufacturing plants, commercial buildings, and industrial sites require precise labeling. Phenolic tags provide permanent identification for control panels, helping technicians quickly locate the right switches and components.

For facilities with multiple panels, circuits, and controls, color-coded phenolic labels help improve organization. A simple red label for emergency shutoffs, blue for main power, and yellow for auxiliary systems can make maintenance safer and more efficient.

4. Emergency and Warning Labels

Regulatory agencies like OSHA and the NEC require proper labeling for safety equipment. Engraved phenolic labels make adding danger signs, emergency shutoff labels, and lockout/tagout instructions to any system easy.

These labels are commonly used for:

- Arc flash warning signs

- Electrical hazard indicators

- Generator and emergency power switches

- Fire alarm system components

Because they are weatherproof and resistant to fading, phenolic labels remain effective even in outdoor or high-traffic environments.

5. Equipment Nameplates and Serial Number Tags

Tracking and maintaining electrical components is easier with custom-engraved serial numbers and nameplates. Phenolic labels can include barcodes, part numbers, and company logos for a professional, organized look.

For businesses that maintain extensive inventories of electrical components, having consistent, engraved identifications simplifies record-keeping, maintenance schedules, and replacement orders.

Custom Engraved Phenolic Labels vs. Other Labeling Methods

There’s a reason electrical professionals trust phenolic labels over stickers, painted markings, or laminated tags.

- Paper and Vinyl Stickers – Cheap but prone to peeling, fading, and smudging over time.

- Metal Labels – Durable but conductive and can corrode in specific environments.

- Painted or Stenciled Markings – Wear off with time and exposure to heat, oils, and cleaning chemicals.

Engraved phenolic labels offer the best of all worlds—they’re permanent, easy to read, non-conductive, and built to last.

Choosing the Right Phenolic Labels for Your Electrical Needs

Before ordering, it’s important to consider a few key factors to ensure that you get the best label for the job.

✔ Size and Shape – Standard sizes work for most applications, but custom cuts are perfect for unique panels.

✔ Color Options—Common combinations for safety labels include black with white text, white with black text, or red.

✔ Mounting Style – Choose from adhesive backing, screw holes, or magnetic options based on installation needs.

✔ Text and Engraving Depth – Deep engraving ensures long-term visibility, even in harsh industrial settings.

For electrical contractors managing multiple projects, having a supplier that offers fast turnaround times and bulk ordering is essential. Customizing labels to match specific job requirements can save time and keep projects on schedule.

Why Custom Engraving Matters

Not all labels are created equal. The clarity and longevity of engraved phenolic labels make them far superior to printed or laminated alternatives.

✔ Crisp, Legible Text – Engraving cuts directly into the material, ensuring letters never fade or rub off.

✔ Fully Customizable – Engrave anything from panel numbers to equipment warnings.

✔ Durability in Harsh Environments – Holds against heat, moisture, and chemical exposure.

For companies that prioritize workplace safety and compliance, investing in high-quality custom labels can help reduce liability risks and improve operational efficiency.

A Long-Term Investment in Safety and Efficiency

A well-organized electrical system starts with clear, durable labels. Phenolic labels reduce the risk of errors and make maintenance and troubleshooting easier. With custom engraving, every panel, breaker, and switch is marked precisely as needed, ensuring compliance, safety, and long-term reliability.

Electrical professionals understand the importance of choosing the right materials for every job. Phenolic labels are a proven solution that withstands the demands of high-voltage environments, industrial settings, and commercial buildings. By investing in high-quality, custom-engraved labels, businesses can create safer workspaces and more efficient electrical systems—a decision that has paid off for years.