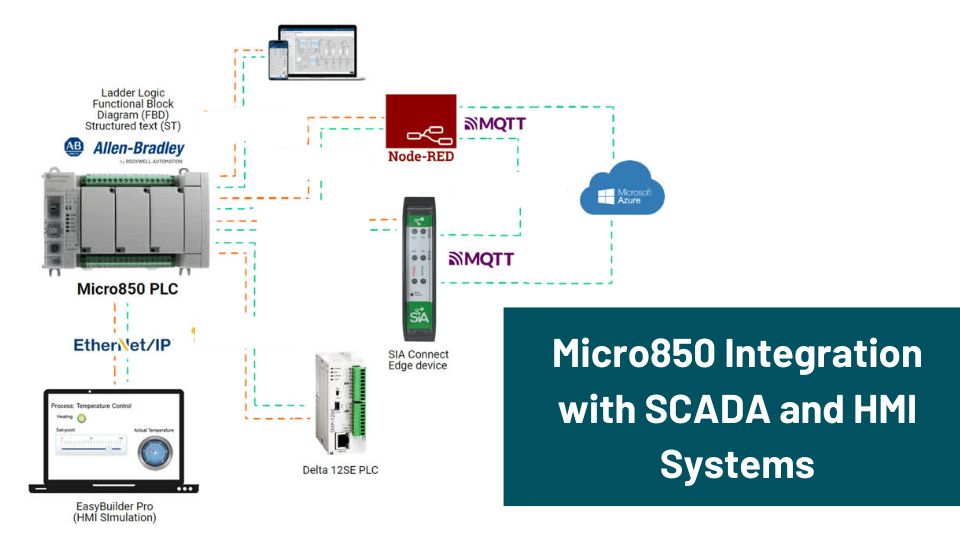

Industrial automation Seamless integration between the controller, SCADA system and HMI interface is essential. The Allen-Bradley Micro850 PLC excels as a powerful and flexible controller. which excels in their integration Whether it is real-time data management increasing operational efficiency or providing an easy-to-use user interface. The Micro850’s compatibility with SCADA and HMI systems is the cornerstone of modern automation strategies.

SCADA Integration with the Micro850

SCADA (Supervisory Control and Data Acquisition) systems are essential for overseeing complex industrial processes, and the Micro850 PLC is designed to work harmoniously with them. Equipped with Ethernet/IP and Modbus TCP/IP protocols, the Micro850 ensures efficient communication with SCADA systems and allows operators to monitor and control processes in real time. The controller’s ability to handle large data exchanges supports applications from small machines to entire production lines.

One of the strengths of the Micro850 is its support for data logging and event monitoring, features that are indispensable for SCADA systems. By recording operational metrics and fault events, the Micro850 provides SCADA operators with valuable insight into process performance and system health. This capability is particularly useful in predictive maintenance scenarios where early identification of anomalies can prevent costly downtime.

The integration process is further simplified by the Allen-Bradley Connected Components Workbench (CCW) software. CCW allows engineers to configure and program the Micro850 in a way that seamlessly meets SCADA requirements. It offers tools for creating tags, configuring communication parameters and ensuring that PLC data is easily accessible to the SCADA system.

HMI Integration with the Micro850

In addition to SCADA, HMI (Human-Machine Interface) systems play a key role in modern automation. HMIs provide operators with an intuitive graphical interface to interact with the automation system. The Micro850 PLC is designed to integrate effortlessly with Allen-Bradley’s PanelView 800 HMI and other compatible HMI devices.

The integration between the Micro850 and the HMI system allows operators to visualize processes, adjust settings and respond to alarms without requiring deep programming knowledge. Using the pre-built libraries and templates available in CCW, engineers can design HMI screens that display data from the Micro850 in real time. These screens can include dynamic graphics, trend graphs and alarm notifications, all tailored to the specific needs of the application.

The Micro850’s ability to handle multiple communication protocols ensures that it can connect to a wide variety of HMI interfaces. For example, the controller supports both serial and Ethernet communication, so it is suitable for both legacy systems and modern interfaces. The use of Modbus RTU or TCP further increases its flexibility and enables seamless interaction with third-party HMIs.

Benefits of Integration

The integration of the Micro850 with SCADA and HMI systems delivers a host of benefits to industrial operations. Enhanced operational efficiency is one of the most significant advantages. By leveraging the controller’s ability to collect, process, and transmit data in real time, operators gain better control over production processes, leading to reduced waste and improved productivity.

Another key benefit is improved decision-making. With SCADA systems providing high-level oversight and HMIs offering detailed, real-time interaction, operators have access to the information they need to make informed decisions quickly. The Micro850 facilitates this by ensuring that data flows seamlessly between the controller and the monitoring systems.

Moreover, the flexibility of the Micro850 allows it to be used in a wide range of industries. From manufacturing and packaging to energy management and water treatment, the controller’s adaptability ensures that it can meet the unique demands of different applications. Its compact design and scalable architecture make it an ideal choice for small to medium-sized systems, while its advanced features ensure it can handle complex tasks.

As industrial automation continues to evolve, the need for scalable and future-ready solutions becomes more pressing. The Micro850 PLC addresses this by offering features such as advanced data handling, remote connectivity, and compatibility with IoT-enabled systems. Its integration capabilities extend beyond traditional SCADA and HMI setups to include cloud-based platforms and edge computing devices.

This future-ready approach ensures that systems using the Micro850 remain relevant in the face of technological advancements. For instance, the ability to connect to cloud-based analytics tools allows operators to gain deeper insights into process performance, while remote monitoring capabilities enable them to oversee operations from anywhere in the world.

Conclusion

The Allen-Bradley Micro850 Programmable Logic Controller (PLC) is an efficient and advanced controller that is capable of SCADA and HMI integration. This is made possible by its excellent communication abilities, user-friendly programming interfaces, and advanced data processing capabilities, which all contribute to making it a central element of systems that require automation to be done effectively and intelligently. The Micro850 helps to eliminate the barriers of operation between people and the processes resulting in high output and less Idleness, as it is flexible to modern industrial challenges.