Printed circuit boards or PCBs form the backbone of modern electronics, connecting components seamlessly to ensure the smooth functioning of devices. Whether it’s your smartphone, laptop, or even your smart watch, PCBs play a crucial role. But as essential as they are, assembling PCBs can be complex and resource-intensive. This is where outsourcing PCB assembly services comes into play.

What are PCB Assembly Services?

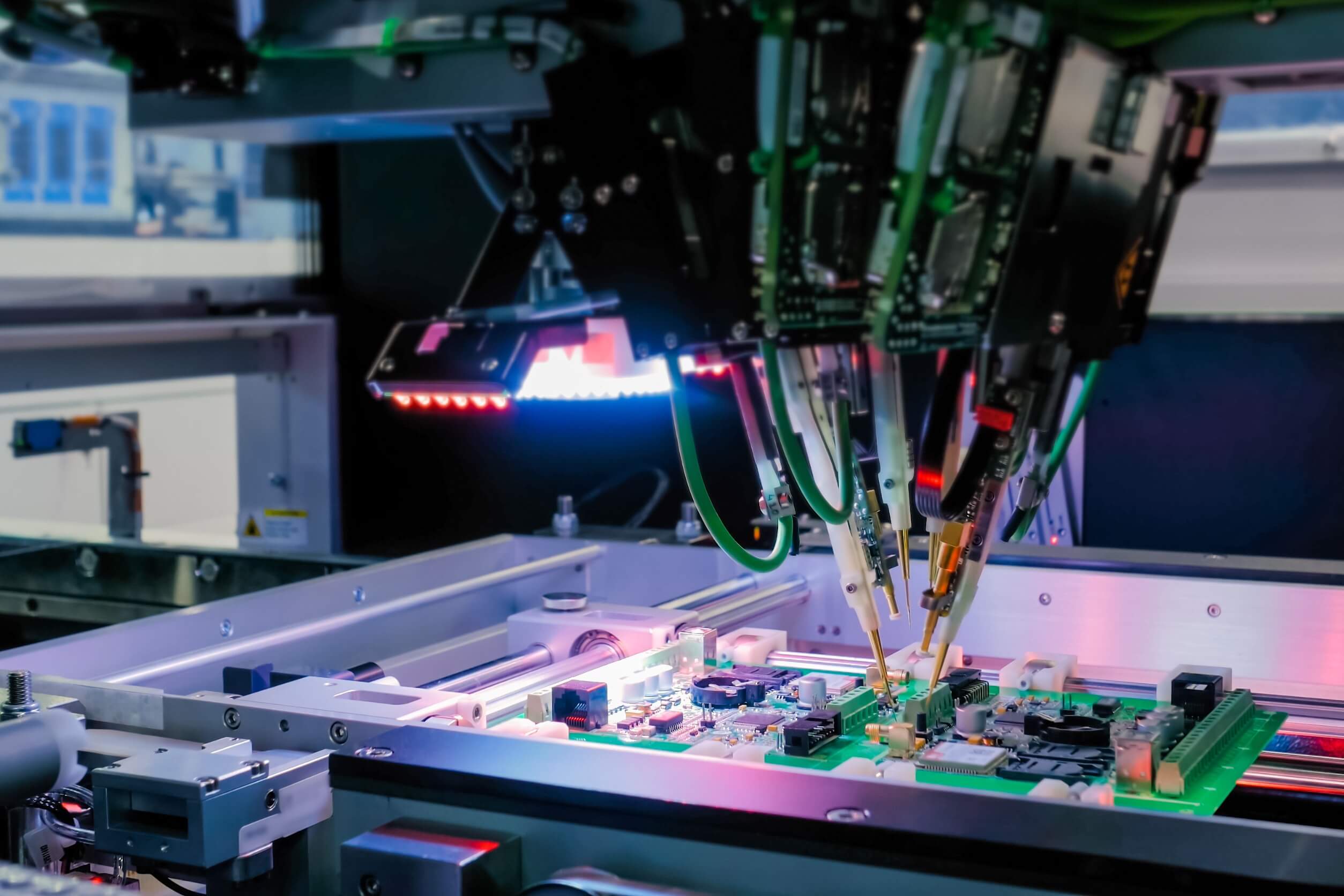

It involves the process of soldering or mounting electronic components onto a PCB. This process can be intricate, requiring precision and expertise. From surface mount technology (SMT) to through-hole assembly, there are various techniques used to assemble PCBs. These services ensure that the final product is reliable and functions as intended.

Outsourcing these services means delegating the task to specialized firms equipped with the necessary tools, expertise, and experience. These firms handle everything from procurement of components to final testing, ensuring the PCBs meet industry standards and specific client requirements.

1. Cost Efficiency

One of the primary reasons companies outsource PCB assembly services is cost efficiency. Setting up an in-house assembly line can be prohibitively expensive. It requires significant investment in machinery, skilled labor, and ongoing maintenance. By outsourcing, companies can save on these initial and operational costs.

Outsourcing also allows businesses to benefit from economies of scale. Specialized PCB assembly firms handle large volumes and can procure components at lower prices. These savings are often passed on to the clients, making it a cost-effective solution.

Further, outsourcing eliminates the need for continuous training and updating of staff to keep up with the latest technologies and standards. This further reduces overhead costs, allowing companies to allocate resources more efficiently.

2. Access to Advanced Technology

Technology in PCB assembly is continually evolving. Staying updated with the latest advancements can be challenging and costly for individual companies. Outsourcing firms, on the other hand, are dedicated to this field and invest heavily in state-of-the-art technologies.

By outsourcing, companies gain access to advanced equipment and techniques without the hefty price tag. These firms employ cutting-edge machinery and software to ensure precision and efficiency in assembly. This not only improves the quality of the PCBs but also speeds up the production process.

Furthermore, advanced technology allows for better testing and quality control. Outsourcing firms use sophisticated testing methods to identify and rectify issues early, ensuring the final product is of the highest quality.

3. Expertise and Experience

PCB assembly is a specialized field requiring a high level of expertise and experience. Outsourcing firms employ professionals who are well-versed in the intricacies of PCB assembly. Their teams are trained to handle various challenges, ensuring the assembly process is smooth and error-free.

These firms have years of experience working with different industries and understanding their unique requirements. This expertise allows them to provide tailored solutions that meet specific client needs. Whether it’s a simple single-layer PCB or a complex multi-layer board, outsourcing firms have the know-how to deliver.

Further, their experience in handling large volumes ensures that they can scale production up or down based on demand. This flexibility is particularly beneficial for companies experiencing fluctuating production needs.

4. Faster Time-to-Market

In today’s fast-paced market, getting a product to market quickly is crucial. Delays in PCB assembly can set back the entire production timeline. Outsourcing helps streamline the process, ensuring faster turnaround times.

Specialized firms have optimized their processes to maximize efficiency. They can handle large volumes without compromising on quality, ensuring that PCBs are assembled and delivered promptly. This speed is particularly beneficial for companies looking to launch new products or meet urgent orders.

Furthermore, outsourcing firms often have established relationships with component suppliers, ensuring timely procurement of necessary parts. This further speeds up the assembly process, allowing companies to get their products to market faster.

5. Focus on Core Competencies

For many companies, PCB assembly is not a core competency. It can divert attention and resources away from their primary business activities. By outsourcing this function, companies can focus on what they do best, leaving the complexities of PCB assembly to the experts.

This focus on core competencies can lead to better overall business performance. Companies can allocate more resources to research and development, marketing, and other critical areas. This not only improves productivity but also drives innovation and growth.

Moreover, outsourcing reduces the burden of managing an in-house assembly line. Companies no longer need to worry about staffing, training, or maintaining equipment. This allows them to operate more efficiently and effectively.

6. Quality Assurance

Quality is paramount when it comes to PCBs. Even minor defects can lead to significant issues in the final product. Outsourcing firms prioritize quality assurance, employing rigorous testing methods to ensure the highest standards.

These firms use advanced testing techniques, including automated optical inspection (AOI), X-ray inspection, and functional testing. This ensures that any defects are identified and rectified early, preventing costly rework or recalls.

Furthermore, outsourcing firms often have certifications and adhere to industry standards, ensuring that the PCBs meet specific quality requirements. This focus on quality assurance gives companies peace of mind, knowing that their PCBs are reliable and high-quality.

Final Thoughts

Outsourcing PCB assembly services offers numerous benefits, from cost efficiency and access to advanced technology to expert knowledge and faster time-to-market. It allows companies to focus on their core competencies while ensuring high-quality PCBs that meet industry standards.

In today’s competitive market, leveraging the expertise and resources of specialized firms can provide a significant advantage. If you are considering outsourcing your PCB assembly, it’s time to take the leap and experience the benefits firsthand.