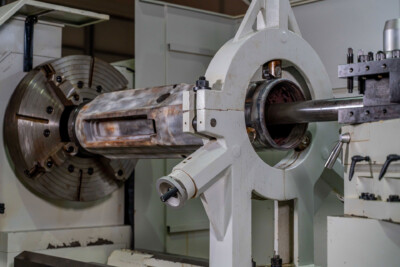

A manual lathe machine is a versatile tool that every workshop should consider. Whether you’re a hobbyist, a small business owner, or a professional machinist, a manual lathe offers numerous advantages. In this blog, we’ll explore the key benefits of using a manual lathe machine in your workshop. We’ll break down each benefit into easy-to-understand sections, making it simple for everyone to grasp why a manual lathe might be the perfect addition to your workspace.

Versatility in Handling Different Projects

One of the standout benefits of a manual lathe machine is its versatility. Unlike specialized machines that are designed for specific tasks, a manual lathe can handle a wide range of projects. Whether you’re turning wood, metal, or plastic, a manual lathe can adapt to your needs.

Wide Range of Materials

Manual lathes can work with various materials, allowing you to experiment and create different types of projects. From crafting delicate wooden pieces to shaping robust metal parts, the manual lathe provides the flexibility needed for diverse tasks.

Customizable Settings

With a manual lathe, you have complete control over the settings. This means you can adjust the speed, feed rate, and cutting tools to suit the specific requirements of each project. This level of customization ensures that you can achieve the desired results every time.

Note – Discover the perfect Manual Lathe Machine for your needs with Raysun Techno Industries LLC. Explore their extensive range of high-quality manual lathes designed to enhance your workshop’s efficiency and precision. Visit Raysun Techno Industries LLC today and take the next step towards achieving outstanding craftsmanship and productivity.

Cost-Effective Tool for Your Workshop

Investing in a manual lathe machine is a cost-effective decision for many workshops. Compared to automated or CNC machines, manual lathes are generally more affordable and offer a high return on investment.

Lower Initial Investment

Manual lathes typically cost less upfront than their automated counterparts. This makes them an excellent choice for small businesses or hobbyists who want to expand their workshop without breaking the bank.

Reduced Maintenance Costs

Manual machines have fewer electronic components, which means they require less maintenance. This not only saves you money on repairs but also ensures that your lathe remains operational for longer periods.

Enhanced Control and Precision

Using a manual lathe gives you a higher level of control over your work compared to automated machines. This control translates into greater precision and accuracy in your projects.

Hands-On Operation

Manual operation allows you to feel the material as you work with it. This tactile feedback helps you make minute adjustments in real-time, leading to more precise and accurate results.

Fine-Tuning Capabilities

With a manual lathe, you can fine-tune every aspect of your project. From adjusting the cutting angle to controlling the feed rate, the manual lathe offers the flexibility to achieve the exact specifications you need.

Improved Skill Development

Operating a manual lathe requires a deep understanding of the machine and the materials you’re working with. This hands-on experience is invaluable for developing and honing your machining skills.

Learning the Basics

Using a manual lathe helps you understand the fundamental principles of machining. This knowledge is crucial for anyone looking to advance in the field of metalworking or woodworking.

Enhancing Problem-Solving Skills

Manual operation often involves troubleshooting and adjusting settings on the fly. This process enhances your problem-solving abilities and makes you more adept at handling unexpected challenges in your projects.

Greater Flexibility in Design and Prototyping

Manual lathes offer unmatched flexibility when it comes to designing and prototyping new ideas. The ability to make quick adjustments and try out different techniques can accelerate the development process.

Rapid Prototyping

With a manual lathe, you can quickly create prototypes of your designs. This allows you to test and refine your ideas without the need for extensive setup times or programming.

Creative Freedom

The manual nature of the lathe gives you the freedom to explore creative designs without being confined by the limitations of automated systems. This creative freedom is essential for innovation and developing unique products.

Durability and Longevity

Manual lathe machines are known for their durability and longevity. Built with sturdy materials, these machines can withstand heavy use and last for many years with proper maintenance.

Robust Construction

Manual lathes are built to handle the stresses of regular use. Their robust construction ensures that they remain reliable and functional even after extensive operation.

Easy Repairs and Upgrades

Due to their simple design, manual lathes are easier to repair and upgrade compared to complex automated machines. This means you can keep your lathe in top condition without significant downtime or expenses.

Enhanced Safety Features

While all machinery carries some risk, manual lathes come with several safety features that help protect the operator. Understanding and utilizing these features can create a safer working environment.

Controlled Operation

Manual lathes require the operator to actively control the machine, which can lead to safer operation. Being engaged in the process helps you stay alert and aware of any potential hazards.

Safety Guards and Features

Most manual lathes come equipped with safety guards and other protective features. These elements help prevent accidents and ensure that you can work with the machine safely.

Eco-Friendly Choice

Manual lathe machines are often more eco-friendly compared to their automated counterparts. They consume less energy and produce fewer emissions, making them a greener choice for your workshop.

Lower Energy Consumption

Manual lathes generally use less electricity than CNC machines. This not only reduces your energy bills but also minimizes your workshop’s carbon footprint.

Minimal Waste Production

With precise control over your projects, manual lathes can help reduce material waste. This efficiency means you make the most of your materials, contributing to a more sustainable workshop.

Ease of Learning and Use

Manual lathes are relatively easy to learn and use, especially for beginners. The straightforward operation allows new users to get up to speed quickly and start creating without a steep learning curve.

User-Friendly Interface

The controls on a manual lathe are simple and intuitive. This user-friendly interface makes it easier for beginners to operate the machine without extensive training.

Accessible Resources

There are plenty of resources available, such as manuals, tutorials, and community forums, to help you learn how to use a manual lathe. This accessibility makes it easier to overcome any challenges you might encounter.

Better Integration with Other Workshop Tools

A manual lathe can seamlessly integrate with other tools in your workshop, enhancing your overall productivity and workflow.

Complementary Equipment

Manual lathes work well alongside other machines like milling machines, drill presses, and grinders. This compatibility allows you to create a cohesive and efficient workshop setup.

Streamlined Workflow

Having a manual lathe in your workshop can streamline your workflow by providing a central hub for shaping and finishing your projects. This centralization can save time and increase your efficiency.

Increased Job Satisfaction

Using a manual lathe can lead to a greater sense of accomplishment and job satisfaction. The hands-on nature of the work allows you to see the direct results of your efforts, which can be highly rewarding.

Creative Expression

Working with a manual lathe gives you the opportunity to express your creativity through your projects. This creative outlet can make your work more enjoyable and fulfilling.

Tangible Results

The ability to create tangible, high-quality products with a manual lathe can boost your confidence and pride in your work. Seeing your projects come to life is a satisfying experience that keeps you motivated.

Conclusion

A manual lathe machine offers numerous benefits that can significantly enhance your workshop’s capabilities. From its versatility and cost-effectiveness to the improved control and skill development it provides, a manual lathe is a valuable tool for any maker. Its durability, safety features, and eco-friendly nature make it a smart investment that will serve you well for years to come. Whether you’re just starting out or looking to upgrade your existing setup, a manual lathe machine can help you achieve your goals with precision and ease.

Embracing the advantages of a manual lathe can transform your workshop, making it a more efficient, creative, and enjoyable place to work. So, if you’re considering adding a new tool to your workshop, a manual lathe machine might just be the perfect choice for you.

For more insightful articles related to this topic, feel free to visit blogsact.com