Choosing the right printed circuit board manufacturer is crucial for any business that relies on electronic components. Whether you are a startup developing your first product or an established company looking to optimize your supply chain, the quality of your PCBs can significantly impact your end products.

What is PCB Manufacturing?

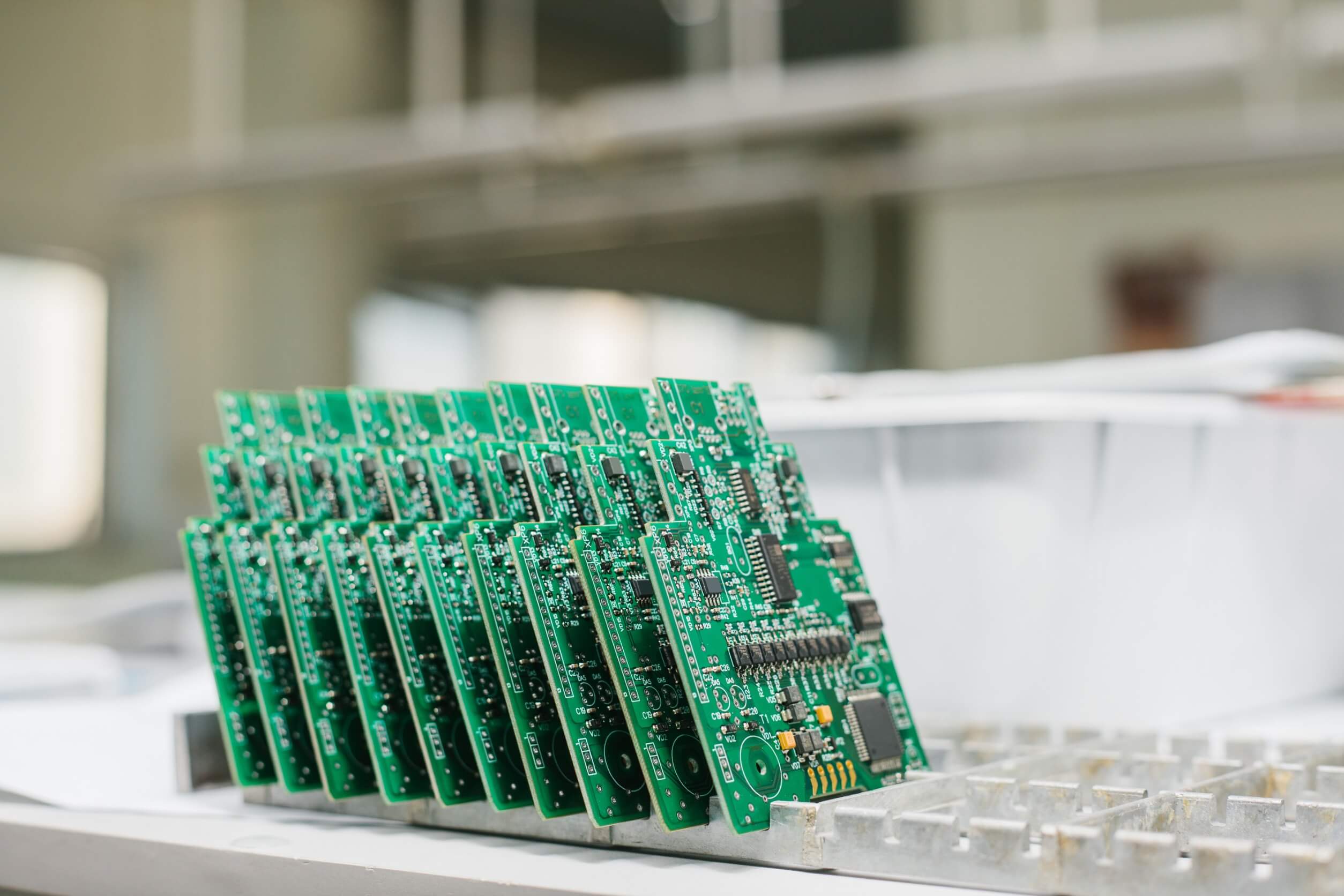

Printed circuit boards are the backbone of modern electronics. They provide mechanical support and electrical connections for electronic components. The manufacturing process involves several stages, from designing the layout to assembling the final product.

The Basics of PCB Manufacturing

The process starts with designing the circuit layout using specialized software. This design is then transferred onto a board made of non-conductive material. Conductive pathways are etched onto the board, creating the circuit that will carry electrical signals.

Key Components of a PCB

A PCB typically consists of multiple layers, each serving a specific purpose. The base layer is usually made of fiberglass, while the conductive layers are made of copper. Additional layers may include solder masks and silkscreen labels to protect and identify components.

Common Types of PCBs

There are several types of PCBs, including single-sided, double-sided, and multi-layer boards. Each type has its own advantages and is suitable for different applications. For instance, multi-layer boards are often used in complex devices like smartphones and computers.

How to Select the Best Printed Circuit Board Manufacturer?

Choosing a PCB manufacturer involves evaluating various factors to ensure you get a reliable and high-quality product. Here are some key considerations:

1. Assessing Manufacturing Capabilities

The first step is to evaluate the manufacturer’s capabilities. Do they offer the specific type of PCB you need? Can they handle the complexity of your design? It’s essential to choose a manufacturer that can meet your technical requirements.

2. Quality Assurance Standards

Quality is non-negotiable when it comes to PCBs. Look for manufacturers that adhere to international quality standards, such as ISO 9001. Certifications are a good indicator that the manufacturer follows stringent quality control processes.

3. Experience and Expertise

Experience matters in PCB manufacturing. A manufacturer with years of experience is likely to have encountered and solved various challenges. They can offer valuable insights and recommendations that can improve your product.

4. Turnaround Time

In today’s fast-paced market, speed is of the essence. Ask about the manufacturer’s lead times and their ability to meet deadlines. A quick turnaround time can give you a competitive edge.

5. Cost Considerations

While cost shouldn’t be the sole deciding factor, it is still important. Compare quotes from multiple manufacturers to find a balance between quality and affordability. Be wary of prices that seem too good to be true.

6. Customer Support

Good customer support can make a significant difference in your overall experience. Choose a manufacturer that offers responsive and helpful customer service. They should be willing to answer your questions and address any concerns promptly.

7. Technological Advancements

The field of PCB manufacturing is constantly evolving. Opt for a manufacturer that stays up-to-date with the latest technological advancements. This ensures that your PCBs will be made using cutting-edge techniques and materials.

8. Customization Options

Every project is unique, and you may require custom solutions. Check if the manufacturer offers customization options to tailor the PCBs to your specific needs. This can include design adjustments, special materials, or unique finishes.

9. Environmental Considerations

Sustainability is becoming increasingly important. Choose a manufacturer that follows environmentally friendly practices. This can include using eco-friendly materials and methods for waste disposal.

10. Reviews and Testimonials

Customer reviews can provide valuable insights into the manufacturer’s reliability and quality. Look for testimonials and case studies that highlight successful projects. These can give you confidence in your choice.

11. Location and Logistics

The manufacturer’s location can impact shipping times and costs. Consider whether a local or international manufacturer is more suitable for your needs. Factor in the logistics to ensure timely delivery.

12. After-Sales Support

After-sales support is crucial for ongoing maintenance and troubleshooting. Ensure that the manufacturer offers comprehensive after-sales services, including technical support and warranty options.

13. Industry Specialization

Some manufacturers specialize in specific industries, such as automotive, aerospace, or medical devices. Choose a manufacturer with expertise in your industry to ensure they understand your unique requirements.

14. Compliance with Regulations

Ensure that the manufacturer complies with all relevant regulations, such as RoHS (Restriction of Hazardous Substances). Compliance is critical to avoid legal issues and ensure product safety.

15. Prototyping Services

Before committing to full-scale production, you may need prototypes to test your design. Check if the manufacturer offers prototyping services. This can save time and money during the development phase.

Final Thoughts

Selecting the best printed circuit board manufacturer is a complex but essential task. By considering factors such as manufacturing capabilities, quality assurance, experience, and customer support, you can make an informed decision that aligns with your business needs. Remember, the right manufacturer can significantly impact the quality and reliability of your products. Start your search today and find the perfect partner to bring your electronic designs to life. You can begin your search by entering the relevant keywords on your fav. search engine.